Menu

ELEVATE FIRE RESISTANCE

PRODUCT SPECIFICATIONS

- OSB panels are available in 4 foot nominal widths and 8, 9, or 10 foot lengths

- Available performance categories: 7/16˝, 15/32˝, and 19/32˝

- Available on APA Exposure 1 rated OSB

Features and Benefits

Resisting Flame Spread

Do More with Less

Exceed Expectations

Design Freedom

Carbon Negative

Sales Tools

Product Catalog

Architectural Specifications

Assembly Reference Guide

Portfolio Product Guide

Technical Documents

Installation Instructions

Rebates

Environmental Product Declaration

Warranty Information

Building for Resiliency

Guide to Fire Resistance

UL Fire Ratings to Know

Factoring Resiliency into Code Requirements

Carbon Negative Product Portfolio

Putting Our Fire-Rated Panels to the Test

See how LP FlameBlock sheathing performs in a controlled product demonstration compared to untreated OSB.

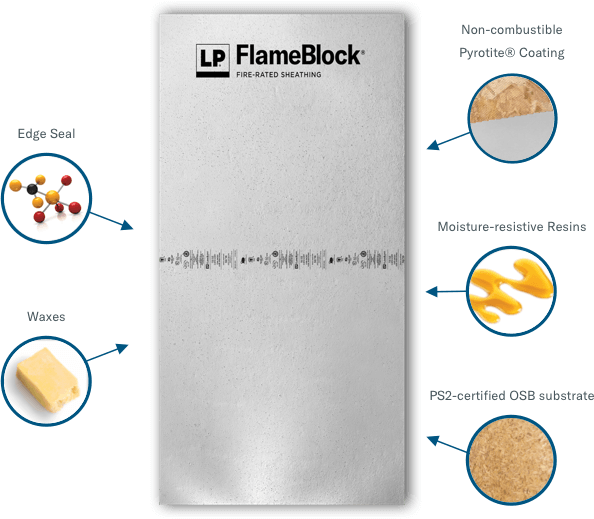

How It’s Made

To create a standard OSB panel, LP’s innovative manufacturing process combines wood strands oriented in cross-directional layers with waxes and resins. Then, to create LP® FlameBlock® panels, LP’s proprietary non-combustible, fiberglass-reinforced Pyrotite® coating is added, which combines flame-spread and burn-through resistance. This creates a product that not only resists fire damage but meets code, provides design flexibility, and also offers the strength and structural integrity of traditional OSB panels.

Fire Resistive Technology

Go to work with a building solution that meets building code requirements for fire-resistant construction while increasing structural ratings. Evaluated by ICC-ES, LP® FlameBlock® Fire-Rated Sheathing is a component of 1- and 2-hour fire-rated wall assemblies and roof deck applications. It combines flame-spread and burn-through resistance to give your customers peace of mind.